1. Casting

After dissolving the ingot, casting using a casting mold the process of producing (Busbar ,Cramp etc.)

2. Post-Processing

Post-treatment (cutting and polishing) process of the castings produced

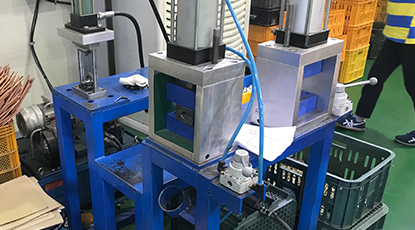

3. Mold Processing

First processed products such as busbar and copperrod Processing with MCT and CNC

4. Plating

Plating process for processed busbars, etc. (outsourcing)

5. Assembly

Primary Assembly (Conductor): Busbar and copperrod Coupling Process

Secondary Assembly (Final): Final Assembly Process for Conductors, insulator, and Gasket

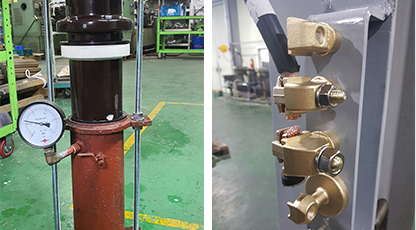

6. Inspection of Finished Products

Inspection of finished product dimensions, appearance, pneumatic, conductivity

7. Packing And Shipping

Packing And Shipping

Material receiving inspection

Import inspection

Melting

Casting

Self-inspection

Post-processing

(Cutting and Polishing)

Self-inspection

| Inspection items | Management item | Management item | Management method | Checker |

|---|---|---|---|---|

| Receiving inspection | INGOT | Compliance with KS standards | Mill Sheet(by lot) | QC manager |

| Self-inspection (casting process) | Castings (busbars, etc.) | Dimensions compared to drawings | Check inspection (first product) | Worker |

| Self-inspection (post-treatment process) | Castings (busbars, etc.) | Appearance defect | Total inspection | Worker |

| Inspection items | Management item | Management item | Management method | Checker |

|---|---|---|---|---|

| Import inspection | Casting, etc | Checking ingredients | Quarterly random inspection | QC manager |

| Dimensions compared to drawings | 1 pcs for each model | QC manager |

Pre-injection inspection

MCT processing

CNC processing

Self-inspection

Plating

Import inspection

| Inspection items | Management item | Management item | Management method | Checker |

|---|---|---|---|---|

| Pre-injection inspection | busbar, etc | Appearance defect status | Full inspection | Worker |

| Dimensions compared to drawings | Check inspection (1 Sample before processing) | Worker | ||

| Self-inspection | busbar, etc | Product surface roughness | Full inspection | Worker |

| Dimensions compared to drawings | Check inspection (first product per lot) | Worker |

| Inspection items | Management item | Management item | Management method | Checker |

|---|---|---|---|---|

| Import inspection | busbar, etc | Self-specification: 10 μm | Mill Sheet (by Lot) | QC manager |

Material receiving inspection

CNC processing

Self-inspection

| Inspection items | Management item | Management item | Management method | Checker |

|---|---|---|---|---|

| Import inspection | rods and nuts | Compliance with KS standards | Mill Sheet (by Lot) | QC manager |

| Dimensions compared to drawings | Check inspection (2pcs per lot) | QC manager | ||

| Self-inspection (CNC process) | rods and nuts | Dimensions compared to drawings | Full inspection | Worker |

| Conneticon diagram of corerod and screw/td> | Check inspection (Worker 1/10pcs) | Worker |

pre-injection inspection

Assembly (conductor)

Self-inspection

Assembly (Final)

Self-inspection

| Inspection items | Management item | Management item | Management method | Checker |

|---|---|---|---|---|

| pre-injection inspection | porcelain tube | Dimensions compared to drawings | Full inspection | Worker |

| Slope and surface defects | Full inspection | Worker | ||

| Self-inspection | Conductor (busbar + corerod) | Assembly Talk | Full inspection | Worker |

| Soldering surface contamination status | Full inspection | Worker | ||

| Final (conductor + insulator + gasket) | Dimensions compared to drawings | Full inspection | Worker |

dimensional inspection

an appearance inspection

pneumatic inspection

Conductivity check

| Inspection items | Management item | Management item | Management method | Checker |

|---|---|---|---|---|

| dimensional inspection | Bushing (finished product) | Dimensions compared to drawings (Within 3% of allowable tolerance non-marking) |

Full inspection | QA manager |

| Appearance inspection | Bushing (finished product) | Assembly status and surface defects | Full inspection | QA manager |

| Pneumatic inspection | Bushing (finished product) | Self-standard: 0.7 MPa | Check inspection (by Lot) | QA manager |

| Conductivity test | Bushing (finished product) |

Customer and Self-Criteria (Net Convergence) - Copper Forging: 95% - Copper casting: 80% - Brass: 24% - Bronze: 13% |

Customer request (1pcs per same lot) | QA manager |

pre-injection inspection

packing

Self-inspection

release

Storage other than forwarding items

| Inspection items | Management item | Management item | Management method | Checker |

|---|---|---|---|---|

| pre-injection inspection | bushing | Quantity identification | Full inspection | Worker |

| Self-inspection | bushing | Packaging status | Full inspection | QC manager |